Our Services

Precision. Compliance. Impact.

At 3N Technical Consulting, LLC, we specialize in delivering practical, reliable, and regulation-ready technical solutions for government agencies, contractors, and industrial clients.

Whether you're sourcing hard-to-find automation components, modernizing outdated control systems, or seeking engineering support for regulated environments — we’re here to help. From basic equipment procurement to advanced engineering design and compliance consulting, our services are built to scale with your needs.

We bridge the gap between technical complexity and operational clarity — so your team can focus on what matters most: delivering results.

Explore our three service tiers to find the right fit for your mission:

Basic: Equipment and parts supply, fully documented and procurement-ready

Intermediate: Technical product consulting and system compatibility guidance

Advanced: Full-service engineering, automation design, and compliance execution

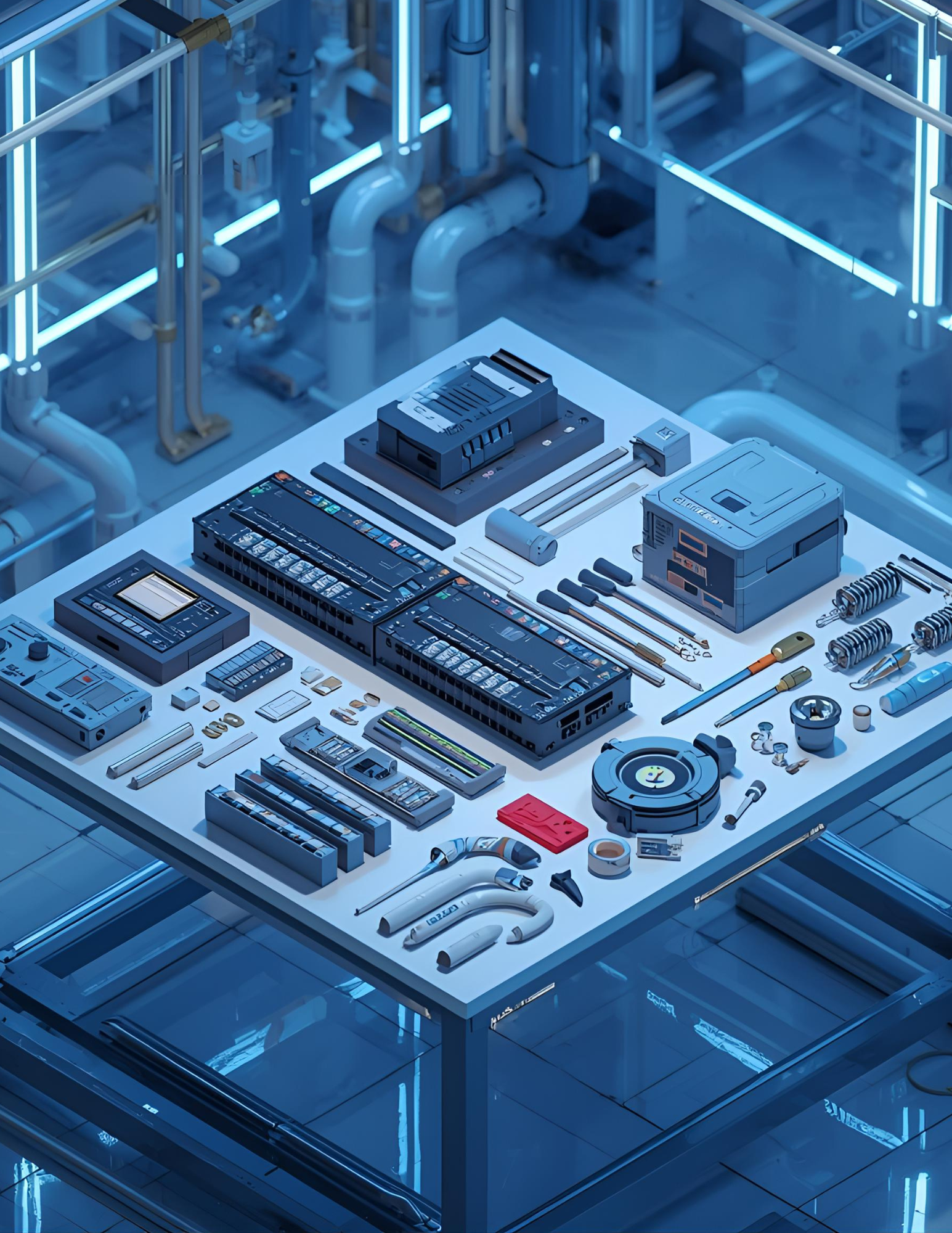

Basic Service Tier: Government Parts & Equipment Supply

Streamlined, compliant, and on-time.

We provide essential components and technical equipment for federal, state, and local government agencies — ensuring reliable sourcing and fast delivery of hard-to-find parts and industry-specific materials.

Key Offerings:

Procurement and resale of automation hardware (PLCs, control modules, HMI panels)

Supply of electrical components, instrumentation, and data historian peripherals

OEM and aftermarket parts acquisition for regulated and industrial environments

Full documentation for compliant procurement (quotes, CAGE/UEI identifiers, DUNS, etc.)

Support for micro-purchases, simplified acquisition thresholds, and FAR-compliant quotes

Use Case Examples:

A military facility needs a replacement I/O module for their automation system

A wastewater treatment plant requires urgent delivery of pressure transducers

A VA hospital requests compliant documentation for purchasing SCADA components

Intermediate Service Tier: Technical Product Consulting

Helping you select the right tools, software, and systems — the first time.

We offer specialized product consultation for agencies and integrators navigating complex industrial environments. Whether you're upgrading legacy systems or designing a new control room, we help you choose technology that fits your needs and your budget.

Key Offerings:

Guidance on selection of PLCs, HMIs, SCADA/DCS software, or historian platforms

Compatibility and lifecycle evaluation for new or replacement parts

Vendor-neutral recommendations (Allen-Bradley, Siemens, DeltaV, PI System, etc.)

Integration strategies for data historians, MES, and ERP systems

Budget-friendly solutions for regulated industries (pharma, food, energy, etc.)

Use Case Examples:

A city utilities department is unsure whether to upgrade their Wonderware system or switch to Ignition

A contractor needs to confirm whether an old Rockwell PanelView HMI is compatible with a new CompactLogix PLC

An FDA-regulated site seeks a GAMP Category 4-compliant data historian setup

Advanced Service Tier: Full-Service Engineering & Compliance Solutions

Design, document, and deliver technical excellence.

From initial concept to qualified implementation, we provide comprehensive engineering solutions tailored for high-stakes environments. Whether you're dealing with FDA validation, ISO compliance, or mission-critical automation upgrades, we bring the expertise to do it right — the first time.

Key Offerings:

Full electrical design packages (schematics, panel layouts, BOMs, cable schedules)

Custom tool development for batch PI point additions, log monitoring, audit trail capture

21 CFR Part 11 & GAMP compliance consulting for pharma-grade systems

Project management for upgrades, commissioning, and qualification

Remote and onsite engineering support for startups, shutdowns, and troubleshooting

Collaboration with OEMs, system integrators, and validation teams

Use Case Examples:

A pharmaceutical plant needs a full FAT/SAT/IOQ documentation package for a new environmental monitoring system

A federal lab requires automated PowerShell tools to capture software change logs across 250+ servers

A water treatment facility needs to replace legacy SCADA systems with minimal operational downtime

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!